Introduction

A diaphragm pump is a type of positive displacement pump that uses a flexible diaphragm and check valves to move fluids.

It is widely used for chemical transfer, wastewater treatment, and process applications where leakage-free operation is critical.

In this article, you’ll learn how a diaphragm pump works, key parts, P&ID symbols, and can download a ready-to-use AutoCAD DWG block for your design projects.

1. What Is a Diaphragm Pump?

A diaphragm pump moves liquid using a reciprocating diaphragm made from rubber, Teflon, or other flexible material.

The diaphragm alternately expands and contracts, creating suction and discharge cycles — allowing fluid to flow in one direction through inlet and outlet check valves.

💡 No mechanical seals are needed, making diaphragm pumps ideal for abrasive, viscous, or corrosive fluids.

2. Working Principle

Step 1: Suction Stroke

-

The diaphragm moves backward.

-

Pressure in the pump chamber drops.

-

Inlet check valve opens, drawing liquid in.

-

Outlet valve closes to prevent backflow.

Step 2: Discharge Stroke

-

The diaphragm moves forward.

-

Pressure increases inside the chamber.

-

Outlet check valve opens, discharging fluid.

-

Inlet valve closes to stop return flow.

Repeat this motion continuously for constant pumping action.

3. Types of Diaphragm Pumps

| Type | Drive Mechanism | Typical Use |

|---|---|---|

| Air-Operated Double Diaphragm (AODD) | Compressed air | Chemical transfer, portable pumps |

| Hydraulically Operated | Hydraulic fluid moves diaphragm | Industrial process, high pressure |

| Mechanically Driven | Cam or crankshaft actuated | Metering and dosing systems |

🧩 The AODD pump is the most common — self-priming, explosion-proof, and capable of dry running.

4. Major Components

| Component | Function |

|---|---|

| Flexible Diaphragm | Separates fluid and air chambers; provides suction and discharge motion |

| Air Valve / Drive Section | Alternates air pressure between diaphragms (AODD type) |

| Inlet & Outlet Check Valves | Ensure one-way flow |

| Manifold & Casing | Channels the fluid |

| Bolts, Seats, and O-Rings | Maintain leak-tight assembly |

5. Advantages

✅ Handles viscous, abrasive, and corrosive fluids

✅ Self-priming and dry-running capability

✅ Portable and explosion-safe (AODD)

✅ No shaft seals → zero leakage

✅ Simple maintenance and compact design

6. Common Applications

-

Chemical and paint transfer

-

Food & beverage production

-

Wastewater treatment plants

-

Oil and gas refineries

-

Pharmaceutical processing

-

Tanker loading and unloading

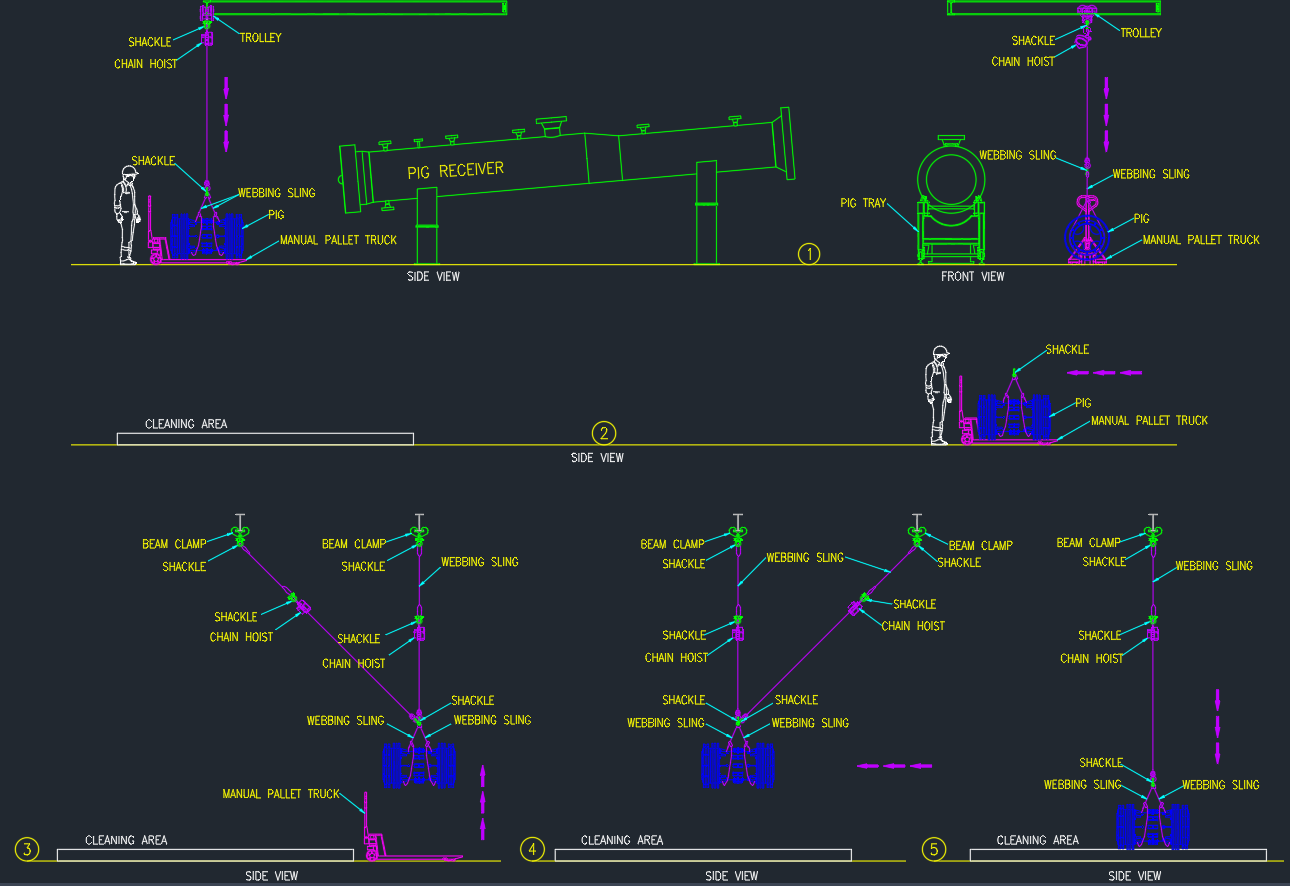

7. P&ID Symbol for Diaphragm Pump

On a Piping & Instrumentation Diagram (P&ID), diaphragm pumps are represented by a circle with a flexible membrane symbol inside.

Typical tag examples:

-

P-101 A/B – Air-Operated Diaphragm Pump

-

P-302 – Metering Diaphragm Pump

The air supply and discharge lines are often annotated in P&IDs to show control logic and pulsation dampers.

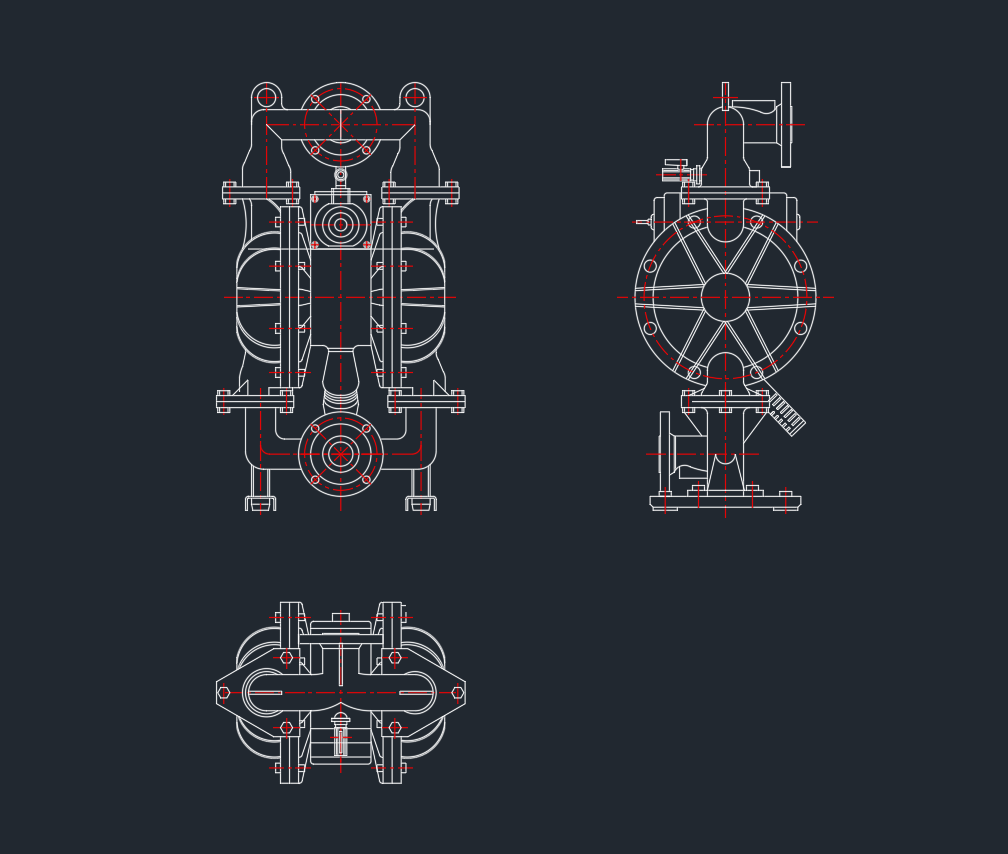

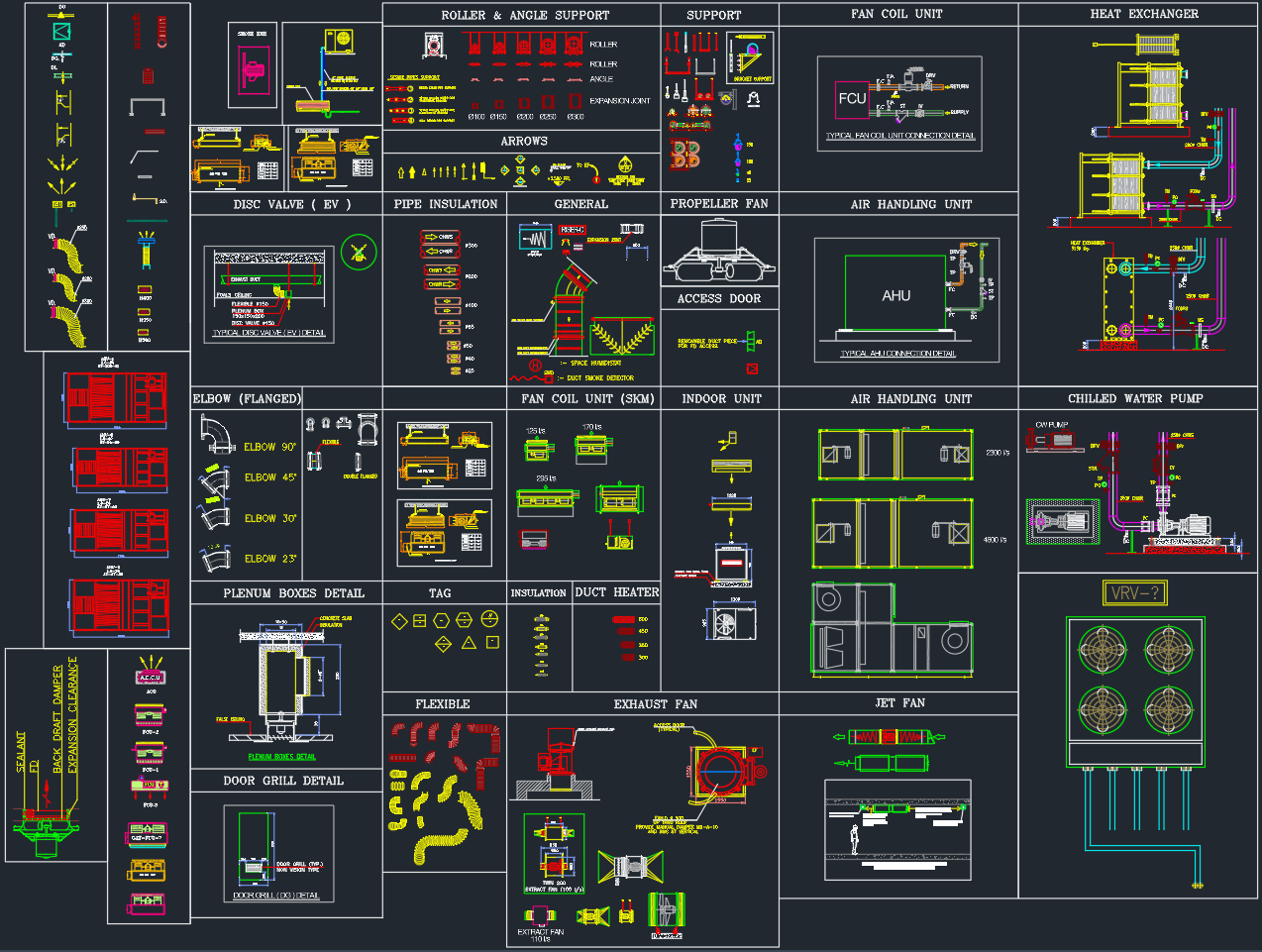

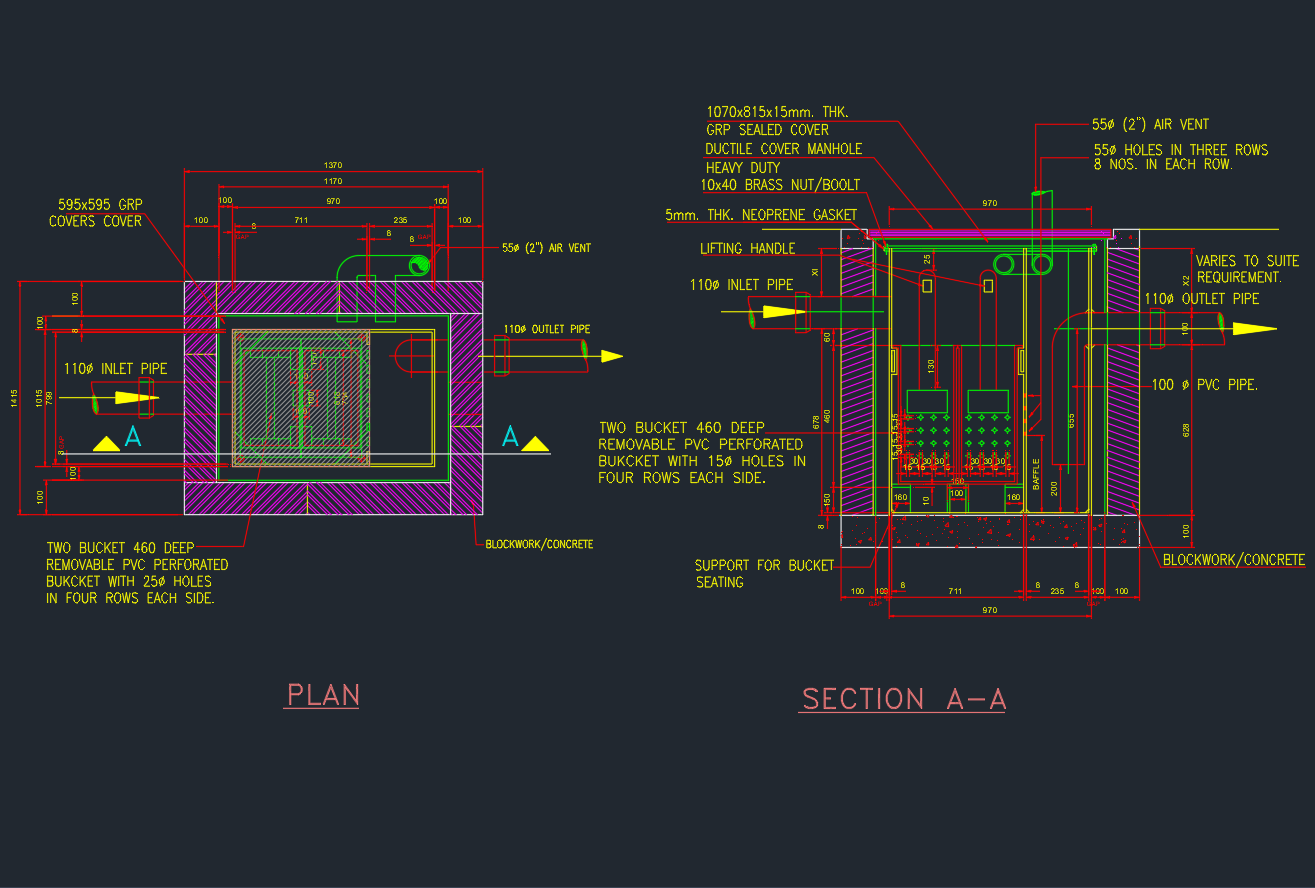

8. AutoCAD DWG Drawing Details

| Feature | Description |

|---|---|

| File Format | .DWG (AutoCAD 2007 or later) |

| Views | Plan, Front Elevation |

| Scale | 1:1 (true size) |

| Layers | Equipment, Centerline, Text |

| Category | Mechanical Equipment / Pumps |

License: Free for personal and educational use

9. Design & Installation Tips

-

Use pulsation dampeners to reduce vibration.

-

Keep suction lines short to improve efficiency.

-

Include pressure gauges and relief valves for safety.

-

Mount on anti-vibration pads for portable or skid setups.

-

Always check compatibility of diaphragm material with pumped fluid.

10. Conclusion

The Diaphragm Pump is a reliable and versatile pumping solution for handling difficult fluids.

Its leak-free design, self-priming capability, and adaptability make it an essential part of industrial, wastewater, and chemical plants.